How it works. Sewerage of a big city. Wastewater treatment plant

Is a complex of special facilities designed for cleaning wastewater from the dirt contained in them. The purified water is either used later or discharged into natural reservoirs (Great Soviet Encyclopedia).

Every locality needs effective treatment facilities. The operation of these complexes determines what kind of water will enter the environment and how this will further affect the ecosystem. If liquid waste is not cleaned at all, then not only plants and animals will die, but the soil will also be poisoned, and harmful bacteria can enter the human body and cause serious consequences.

Every business that has toxic liquid waste is required to deal with the system treatment facilities... Thus, it will reflect on the state of nature, and improve human living conditions. If the treatment facilities operate efficiently, the wastewater will become harmless when it gets into the ground and water bodies. The size of treatment facilities (hereinafter referred to as OS) and the complexity of treatment strongly depend on the pollution of wastewater and their volumes. In more detail about the stages of wastewater treatment and the types of O.S. read on.

Wastewater treatment stages

The most indicative in terms of the presence of stages of water purification are urban or local OS, designed for large settlements. It is household wastewater that is most difficult to purify, as it contains diverse pollutants.

For sewage water treatment facilities, it is characteristic that they are built in a certain sequence. Such a complex is called a line of treatment facilities. The diagram starts with mechanical cleaning... Here, gratings and sand traps are most often used. This is the initial stage of the entire water treatment process.

These can be leftover paper, rags, cotton wool, bags, and other debris. After the gratings, sand traps come into operation. They are necessary in order to retain sand, including large ones.

Mechanical stage of wastewater treatment

Initially, all water from the sewage system goes to the main pumping station in a special tank. This reservoir is designed to compensate for the increased load during peak hours. A powerful pump evenly pumps the appropriate volume of water for all stages of cleaning.

Initially, all water from the sewage system goes to the main pumping station in a special tank. This reservoir is designed to compensate for the increased load during peak hours. A powerful pump evenly pumps the appropriate volume of water for all stages of cleaning.

catch large debris over 16 mm - cans, bottles, rags, bags, food, plastic, etc. In the future, this garbage is either processed on site, or taken out to the places where solid household and industrial waste is processed. Lattices are a type of transverse metal beams, the distance between which is equal to several centimeters.

catch large debris over 16 mm - cans, bottles, rags, bags, food, plastic, etc. In the future, this garbage is either processed on site, or taken out to the places where solid household and industrial waste is processed. Lattices are a type of transverse metal beams, the distance between which is equal to several centimeters.

In fact, they catch not only sand, but also small pebbles, glass fragments, slag, etc. The sand settles to the bottom rather quickly under the influence of gravity. Then the settled particles are raked into a depression at the bottom by a special device, from where they are pumped out by a pump. The sand is washed and disposed of.

In fact, they catch not only sand, but also small pebbles, glass fragments, slag, etc. The sand settles to the bottom rather quickly under the influence of gravity. Then the settled particles are raked into a depression at the bottom by a special device, from where they are pumped out by a pump. The sand is washed and disposed of.

... It removes all impurities that float to the surface of the water (fats, oils, oil products, etc.), etc. By analogy with a sand trap, they are also removed with a special scraper, only from the water surface.

... It removes all impurities that float to the surface of the water (fats, oils, oil products, etc.), etc. By analogy with a sand trap, they are also removed with a special scraper, only from the water surface.

4. Sediments - an important element of any line of wastewater treatment plants. They release water from suspended solids, including helminth eggs. They can be vertical and horizontal, single-deck and double-deck. The latter are the most optimal, since the water from the sewerage system in the first tier is purified, and the sediment (sludge) that has formed there is discharged through a special hole into the lower tier. How does the process of releasing water from the sewage system from suspended solids occur in such structures? The mechanism is pretty simple. Sediment tanks are large-sized tanks of round or rectangular shape, where sedimentation of substances under the influence of gravity occurs.

To speed up this process, you can use special additives - coagulants or flocculants. They promote adhesion of small particles due to a change in charge, larger substances precipitate faster. Thus, sedimentation tanks are irreplaceable structures for water purification from the sewage system. It is important to take into account that they are also actively used for simple water treatment. The principle of operation is based on the fact that water enters from one end of the device, while the diameter of the pipe at the outlet becomes larger and the fluid flow slows down. All this contributes to the deposition of particles.

mechanical wastewater treatment can be used depending on the degree of water pollution and the design of a particular treatment plant. These include: membranes, filters, septic tanks, etc.

mechanical wastewater treatment can be used depending on the degree of water pollution and the design of a particular treatment plant. These include: membranes, filters, septic tanks, etc.

If we compare this stage with conventional water treatment for drinking purposes, then in the latter version such structures are not used, they are not necessary. Instead, processes of clarification and discoloration of water take place. Mechanical cleaning is very important, as in the future it will allow more efficient biological cleaning.

Biological wastewater treatment plant

Biological treatment can be both an independent treatment plant and an important stage in a multi-stage system of large urban treatment complexes.

The essence of biological treatment is to remove various pollutants (organic matter, nitrogen, phosphorus, etc.) from the water using special microorganisms (bacteria and protozoa). These microorganisms feed on harmful impurities in the water, thereby purifying it.

From a technical point of view, biological treatment is carried out in several stages:

- a rectangular tank, where water after mechanical cleaning is mixed with activated sludge (special microorganisms), which purifies it. Microorganisms are of 2 types:

- a rectangular tank, where water after mechanical cleaning is mixed with activated sludge (special microorganisms), which purifies it. Microorganisms are of 2 types:

- Aerobic - using oxygen for water purification. When using these microorganisms, the water must be enriched with oxygen before entering the aerotank.

- Anaerobic - DO NOT use oxygen for water purification.

It is necessary to remove unpleasant smelling air and then purify it. This workshop is necessary when the volume of wastewater is large enough and / or treatment facilities are located near settlements.

Here the water is purified from active sludge by settling it. Microorganisms settle to the bottom, where they are transported to the pit using a bottom scraper. A surface scraper mechanism is provided to remove floating sludge.

Here the water is purified from active sludge by settling it. Microorganisms settle to the bottom, where they are transported to the pit using a bottom scraper. A surface scraper mechanism is provided to remove floating sludge.

The cleaning scheme also includes sludge digestion. Of the treatment facilities, a digester is important. It is a reservoir for the fermentation of sludge, which is formed during settling in two-tier primary sedimentation tanks. The digestion process generates methane that can be used in other processing steps. The resulting sludge is collected and transported to special areas for thorough drying. For sludge dewatering, sludge platforms and vacuum filters are widely used. After that, it can be disposed of or used for other needs. Fermentation occurs under the influence of active bacteria, algae, oxygen. Biofilters may also be included in the sewage water treatment scheme.

The cleaning scheme also includes sludge digestion. Of the treatment facilities, a digester is important. It is a reservoir for the fermentation of sludge, which is formed during settling in two-tier primary sedimentation tanks. The digestion process generates methane that can be used in other processing steps. The resulting sludge is collected and transported to special areas for thorough drying. For sludge dewatering, sludge platforms and vacuum filters are widely used. After that, it can be disposed of or used for other needs. Fermentation occurs under the influence of active bacteria, algae, oxygen. Biofilters may also be included in the sewage water treatment scheme.

It is best to place them before the secondary sedimentation tanks, so that the substances that are carried away with the water flow from the filters can settle in the sedimentation tanks. It is advisable to use the so-called pre-aerators to speed up the cleaning. These are devices that contribute to the saturation of water with oxygen to accelerate the aerobic processes of oxidation of substances and biological purification. It should be noted that water purification from the sewage system is conventionally divided into 2 stages: preliminary and final.

The treatment plant system can include biofilters instead of filtration and irrigation fields.

- these are devices where waste water is treated by passing through a filter containing active bacteria. It consists of solid substances, which can be granite chips, polyurethane foam, foam and other substances. On the surface of these particles, a biological film is formed, consisting of microorganisms. They decompose organic matter. Biofilters need to be cleaned periodically as they become dirty.

Waste water is fed into the filter in a metered dose, otherwise a high pressure can destroy beneficial bacteria. After biofilters, secondary sedimentation tanks are used. The sludge formed in them enters partly into the aeration tank, and the rest of it goes to the sludge compactors. The choice of a particular method of biological treatment and the type of treatment facilities largely depends on the required degree of wastewater treatment, relief, type of soil and economic indicators.

Wastewater post-treatment

After passing the main stages of treatment, 90-95% of all contaminants are removed from wastewater. But the remaining pollutants, as well as residual microorganisms and their waste products, do not allow this water to be discharged into natural water bodies. In this regard, various systems for additional wastewater treatment were introduced at the treatment facilities.

The following pollutants are oxidized in bioreactors:

- organic compounds that were too tough for microorganisms,

- these microorganisms themselves,

- ammonium nitrogen.

This happens by creating conditions for the development of autotrophic microorganisms, i.e. converting inorganic compounds into organic. For this, special plastic filling discs with a high specific surface area are used. Simply put, these are discs with a hole in the center. Intensive aeration is used to speed up the processes in the bioreactor.

Filters purify water using sand. The sand is continuously updated in automatic mode. Filtration is carried out in several installations by supplying water to them from the bottom up. In order not to use pumps and not consume electricity, these filters are installed at a lower level than other systems. Filters are flushed in such a way that it does not require a large amount of water. Therefore, they do not occupy such a large area.

UV disinfection of water

Disinfection or disinfection of water is an important component that ensures its safety for the reservoir into which it will be discharged. Disinfection, that is, the destruction of microorganisms, is the final stage in the purification of sewage drains. A wide variety of methods can be used for disinfection: ultraviolet irradiation, alternating current, ultrasound, gamma irradiation, chlorination.

UFO is a very effective method by which about 99% of all microorganisms are destroyed, including bacteria, viruses, protozoa, helminth eggs. It is based on the ability to destroy the membrane of bacteria. But this method is not widely used. In addition, its effectiveness depends on the turbidity of the water, the content of suspended solids in it. And UFO lamps quickly become covered with a coating of mineral and biological substances. To prevent this, special emitters of ultrasonic waves are provided.

The chlorination method is most often used after treatment facilities. Chlorination is different: double, superchlorination, with preammonization. The latter is necessary to prevent unpleasant odors. Superchlorination involves exposure to very high doses of chlorine. The double action is that the chlorination is carried out in 2 stages. This is more typical for water treatment. The method of chlorination of water from the sewage system is very effective, in addition, chlorine has an aftereffect, which other cleaning methods cannot boast. After disinfection, the effluent is drained into the reservoir.

Phosphate removal

Phosphates are salts of phosphoric acids. They are widely used in synthetic detergents (washing powders, dishwashing detergents, etc.). Phosphates, getting into water bodies, lead to their eutrophication, i.e. turning into a swamp.

Wastewater purification from phosphates is carried out by the dosed addition of special coagulants to the water in front of biological treatment facilities and in front of sand filters.

Auxiliary rooms of treatment facilities

Aeration workshop

Is an active process of saturating water with air, in this case by passing air bubbles through the water. Aeration is used in many processes in sewage treatment plants. Air supply is carried out by one or more blowers with frequency converters. Special oxygen sensors regulate the amount of air supplied so that its content in the water is optimal.

Is an active process of saturating water with air, in this case by passing air bubbles through the water. Aeration is used in many processes in sewage treatment plants. Air supply is carried out by one or more blowers with frequency converters. Special oxygen sensors regulate the amount of air supplied so that its content in the water is optimal.

Disposal of excess activated sludge (microorganisms)

At the biological stage of wastewater treatment, excess sludge is formed, since microorganisms in aeration tanks actively multiply. Excess sludge is dewatered and disposed of.

The dehydration process takes place in several stages:

- The excess sludge is added special reagentswhich suspend the activity of microorganisms and contribute to their thickening

- IN sludge compactor sludge is compacted and partially dewatered.

- On centrifuge The sludge is squeezed out and the remaining moisture is removed from it.

- In-line dryers by continuous circulation warm air the sludge is finally dried. The dried sludge has a residual moisture content of 20-30%.

- Then ooze packed in sealed containers and disposed of

- The water removed from the sludge is sent back to the beginning of the cleaning cycle.

Air cleaning

Unfortunately, sewage treatment plants don't smell their best. Particularly smelly is the biological wastewater treatment stage. Therefore, if the treatment plant is located near settlements or the volume of wastewater is so large that a lot of bad-smelling air is formed, you need to think about cleaning not only water, but also air.

Air purification usually takes place in 2 stages:

- The initially polluted air is fed into bioreactors, where it comes into contact with a specialized microflora adapted for the disposal of organic matter contained in the air. It is these organic substances that cause the bad smell.

- The air goes through a stage of disinfection with ultraviolet light to prevent these microorganisms from entering the atmosphere.

Wastewater treatment plant laboratory

All water that leaves the treatment plant must be systematically controlled in the laboratory. The laboratory determines the presence of harmful impurities in the water and the compliance of their concentration with the established standards. If one or another indicator is exceeded, the workers of the treatment plant conduct a thorough examination of the corresponding cleaning stage. And in case of a malfunction, they eliminate it.

Administrative complex

The staff serving the treatment plant can reach several dozen people. For their comfortable work, an administrative and amenity complex is being created, it includes:

- Equipment repair workshops

- Laboratory

- Control room

- Offices of administrative and managerial personnel (accounting, HR, engineering, etc.)

- Head office.

Power supply O.S. performed according to the first category of reliability. Since the long shutdown of the work of O.S. due to lack of electricity can cause the OS to go out. out of service.

To prevent emergencies, the power supply of O.S. carried out from several independent sources. In the department of the transformer substation, a power cable is provided from the city power supply system. And also the input of an independent source of electric current, for example, from a diesel generator, in case of an accident in the city power grid.

Conclusion

Based on the foregoing, it can be concluded that the scheme of treatment facilities is very complex and includes various stages of wastewater treatment from the sewage system. First of all, you need to know that this scheme applies only to domestic wastewater. If there are industrial effluents, then in this case they additionally include special methods that will be aimed at reducing the concentration of hazardous chemicals. In our case, the cleaning scheme includes the following main stages: mechanical, biological cleaning and disinfection (disinfection).

Mechanical cleaning begins with the use of gratings and sand traps, in which large debris (rags, paper, cotton wool) is retained. Sand traps are needed to sediment excess sand, especially coarse sand. This is of great importance for the subsequent steps. After the gratings and sand traps, the sewage treatment plant scheme includes the use of primary sedimentation tanks. Suspended substances settle in them under the force of gravity. To speed up this process, coagulants are often used.

After the sedimentation tanks, the filtration process begins, which is carried out mainly in biofilters. The mechanism of action of the biofilter is based on the action of bacteria that destroy organic matter.

The next stage is secondary sedimentation tanks. In them, the sludge, which was carried away with the current of liquid, settles. After them, it is advisable to use a digester, the sediment is fermented in it and transported to the sludge pads.

The next stage is biological treatment using an aeration tank, filtration fields or irrigation fields. The final stage is disinfection.

Types of treatment facilities

A variety of structures are used for water treatment. If it is planned to carry out these works in relation to surface waters immediately before their supply to the distribution network of the city, then the following structures are used: sedimentation tanks, filters. A wider range of devices can be used for wastewater: septic tanks, aeration tanks, digestion tanks, biological ponds, irrigation fields, filtration fields, and so on. Treatment facilities are of several types, depending on their purpose. They differ not only in the volumes of purified water, but also in the presence of stages of its purification.

Urban Wastewater Treatment Plant

Data by O.S. are the largest of all, they are used in large metropolitan areas and cities. In such systems, particularly effective methods of liquid purification are used, for example, chemical treatment, methane tanks, flotation units. They are intended for the treatment of municipal wastewater. These waters are a mixture of domestic and industrial wastewater. Therefore, there are a lot of pollutants in them, and they are very diverse. The waters are purified to the standards for discharge into the fishery water body. The standards are regulated by the order of the Ministry of Agriculture of Russia dated 13.12.2016 No. 552 "On approval of water quality standards for water bodies of fishery significance, including standards for maximum permissible concentrations of harmful substances in waters of water bodies for fishery significance."

On OS data, as a rule, all stages of water purification described above are used. The most illustrative example is the Kuryanovsk treatment plant.

Kuryanovskiye O.S. are the largest in Europe. Its capacity is 2.2 million m3 / day. They serve 60% of the wastewater in Moscow. The history of these objects goes back to 1939.

Local treatment facilities

Local treatment facilities are structures and devices designed for the treatment of subscriber's wastewater before being discharged into the municipal sewage system (the definition is given by the Decree of the Government of the Russian Federation of February 12, 1999, No. 167).

There are several classifications of local OS, for example, there are local OS. connected to the central sewerage and autonomous. Local OS can be used at the following facilities:

- In small towns

- In villages

- In sanatoriums and boarding houses

- At car washes

- On personal plots

- At manufacturing plants

- And at other sites.

Local OS can be very different from small units to permanent structures, which are serviced by qualified personnel on a daily basis.

Treatment facilities for a private house.

Several solutions are used for the disposal of wastewater from a private house. They all have their own advantages and disadvantages. However, the choice always rests with the owner of the house.

1. Cesspool... In truth, this is not even a sewage treatment plant, but just a temporary storage tank. When the pit is filled, a sewer truck is called, which pumps out the contents and takes them for further processing.

This archaic technology is still used today because of its cheapness and simplicity. However, it also has significant drawbacks, which, at times, negate all its advantages. Wastewater can enter the environment and the groundwaterthus polluting them. For a sewage truck, you need to provide a normal entrance, since you will have to call it quite often.

2. Storage... It is a container made of plastic, fiberglass, metal or concrete, where waste water is drained and stored. Then they are pumped out and disposed of by a sewer truck. The technology is similar to a cesspool, but the waters do not pollute the environment. The disadvantage of such a system is the fact that in spring, with a large amount of water in the ground, the drive can be squeezed out to the surface of the earth.

3. Septic tank - is a large container, in which substances such as coarse dirt, organic compounds, stones and sand leave in the sediment, and elements such as various oils, fats and oil products remain on the surface of the liquid. The bacteria that live inside the septic tank extract oxygen for life from the precipitated sediment, while reducing the level of nitrogen in the wastewater. When the liquid leaves the sump, it becomes clarified. Then it is purified with bacteria. However, it is important to understand that phosphorus remains in such water. For final biological treatment, irrigation fields, filtration fields or filter wells can be used, the work of which is also based on the action of bacteria and activated sludge. It will not be possible to grow deep-rooted plants in this area.

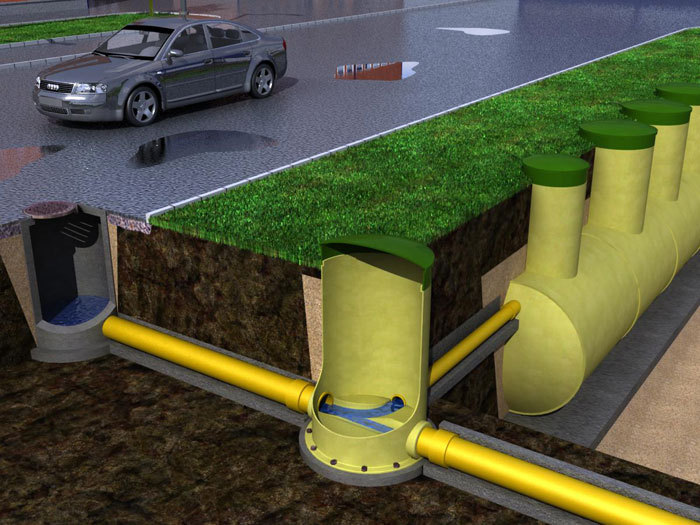

The septic tank is very expensive and can take up a large area. It should be borne in mind that this is a structure that is designed to treat a small amount of domestic wastewater from the sewage system. However, the result is worth the investment. More clearly, the septic tank device is reflected in the figure below.

4. Station of deep biological treatment are already a more serious treatment plant in contrast to a septic tank. This device requires electricity to operate. However, the quality of water purification is up to 98%. The design is quite compact and durable (up to 50 years of operation). There is a special hatch above the ground for servicing the station.

4. Station of deep biological treatment are already a more serious treatment plant in contrast to a septic tank. This device requires electricity to operate. However, the quality of water purification is up to 98%. The design is quite compact and durable (up to 50 years of operation). There is a special hatch above the ground for servicing the station.

Stormwater treatment plant

Despite the fact that rainwater is considered quite clean, it collects various harmful elements from asphalt, roofs and lawns. Garbage, sand and oil products. In order to prevent all this from getting into the nearest reservoirs and storm treatment facilities are being created.

In them, water undergoes mechanical treatment in several stages:

- Sump. Here, under the influence of the Earth's gravity, large particles settle to the bottom - pebbles, glass fragments, metal parts, etc.

- Thin layer module. Here oils and petroleum products are collected on the surface of the water, where they are collected on special hydrophobic plates.

- Sorption fibrous filter. It picks up everything that the thin layer filter missed.

- Coalescing module. It promotes the separation of oil particles that float to the surface, the size of which is greater than 0.2 mm.

- Post-treatment carbon filter. It finally relieves water of all oil products that remain in it after passing through the previous stages of purification.

Wastewater treatment plant design

Design by O.S. determine their cost, choose the right treatment technology, ensure the reliability of the structure, bring wastewater to quality standards. Experienced specialists will help you find efficient installations and reagents, draw up a wastewater treatment scheme and commission the installation. Another important point is budgeting, which will allow you to plan and control costs, as well as make adjustments if necessary.

For the project of O.S. the following factors are strongly influenced:

- Wastewater volumes. Designing structures for a private plot is one thing, but designing a wastewater treatment plant for a cottage village is another. Moreover, it should be borne in mind that the capabilities of O.S. must be greater than the current amount of wastewater.

- Terrain. Wastewater treatment facilities require a special vehicle entrance. It is also necessary to provide for the power supply of the facility, the discharge of treated water, the location of the sewerage system. O.S. can occupy a large area, but they should not interfere with neighboring buildings, structures, road sections and other structures.

- Wastewater pollution.Storm water treatment technology is very different from the treatment of household water.

- Required cleaning level. If the customer wants to save on the quality of the treated water, then it is necessary to use simple technologies. However, if it is necessary to discharge water into natural reservoirs, then the quality of treatment should be appropriate.

- The competence of the performer. If you order OS from inexperienced companies, then get ready for unpleasant surprises in the form of an increase in construction estimates or a septic tank that floated in the spring. This happens because they forget to include critical points in the project.

- Technological features. The technologies used, the presence or absence of treatment stages, the need to build systems serving the treatment plant - all this should be reflected in the project.

- Other. It is impossible to foresee everything in advance. As the design and installation of the treatment plant progresses, various changes may be made to the draft plan that could not have been foreseen at the initial stage.

Treatment plant design stages:

- Preliminary work. They include the study of the object, clarification of the customer's wishes, analysis of wastewater, etc.

- Collection of permits. This item is usually relevant for the construction of large and complex structures. For their construction, it is necessary to obtain and agree on the relevant documentation from the supervisory authorities: MOBVU, MOSRYBVOD, Rosprirodnadzor, SES, Hydromet, etc.

- Choice of technology. On the basis of paragraphs 1 and 2. there is a choice of the necessary technologies used for water purification.

- Budgeting.Construction costs OS must be transparent. The customer must know exactly how much the materials cost, what is the price of the installed equipment, what is the wage fund for workers, etc. You should also consider the costs of subsequent maintenance of the system.

- Cleaning efficiency. Despite all calculations, the cleaning results may be far from desired. Therefore, already at the planning stage, O.S. it is necessary to conduct experiments and laboratory studies that will help to avoid unpleasant surprises after the completion of construction.

- Development and approval of project documentation. To start the construction of treatment facilities, it is necessary to develop and approve the following documents: a project of a sanitary protection zone, a draft of permissible discharge standards, a project of maximum permissible emissions.

Installation of treatment facilities

After the project of O.S. was prepared and that's it required permissions were received, the stage of installation begins. Although the installation of a country septic tank is very different from the construction of a treatment plant in a cottage village, they still go through several stages.

First, the terrain is being prepared. A pit is being dug to install a treatment plant. The floor of the pit is covered with sand and compacted or concreted. If the treatment plant is designed for a large amount of wastewater, then, as a rule, it is erected on the surface of the earth. In this case, the foundation is poured and a building or structure is already installed on it.

Secondly, the equipment is being installed. It is installed, connected to the sewerage and sewerage system, to electrical network... This stage is very important because it requires the personnel to know the specifics of the operation of the configured equipment. It is incorrect installation that most often causes equipment failure.

Thirdly, the verification and delivery of the object. After installation, the finished wastewater treatment plant is tested for the quality of water purification, as well as for the ability to work under increased stress. After checking OS. handed over to the customer or his representative, and also, if necessary, undergoes the state control procedure.

Treatment plant maintenance

Like any equipment, a sewage treatment plant also needs maintenance. First of all, from O.S. it is necessary to remove large debris, sand, as well as excess sludge that forms during cleaning. On large OS the number and variety of removed elements can be much larger. But in any case, you will have to delete them.

Secondly, the equipment is checked for operability. Malfunctions in any element can be fraught not only with a decrease in the quality of water treatment, but also with the failure of all equipment.

Thirdly, in the event of a breakdown, the equipment must be repaired. And it's good if the equipment is under warranty. If the warranty period has expired, then the repair of OS. will have to be done at your own expense.

PURPOSE, TYPES OF TREATMENT FACILITIES AND CLEANING METHODS

A person in the process of his life uses water for his various needs. When used directly, it becomes polluted, its composition and physical properties change. For the sanitary well-being of people, these effluents are diverted from settlements. In order not to pollute the environment, they are processed at special complexes.

Fig. 7 Wastewater treatment facilities of JSC "Tatspirtprom" Usadskiy distillery Republic of Tatarstan 1500 m3 / day

Cleaning steps:

- mechanical;

- biological;

- deep;

- UV disinfection of effluents and further release into the reservoir, dehydration and disposal of sludge.

Production of beer, juices, kvass, various drinks

Cleaning steps:

- mechanical;

- physical and chemical;

- biological and further release to the municipal collector;

- collection, dehydration and disposal of sludge.

Also on this topic read the articles

STORM CLEANING FACILITIES

VOC is a combined tank, or several separate tanks for the treatment of storm and melt water. The qualitative composition of storm runoff is mainly oil products and suspended solids from industrial production and residential areas. They, according to the law, must be cleared before VAT.

The device of storm water treatment facilities is being modernized every year, due to the increase in the number of cars, shopping centers, industrial sites.

The standard set of equipment for stormwater treatment plants is a chain of a distribution well, a sand separator, a gas oil separator, a sorption filter and a sampling well.

Many companies currently use a combined wastewater treatment system. Single-hull VOC is a container, divided internally by partitions into sections of a sand trap, an oil-oil separator and a sorption filter. In this case, the chain looks as follows: a distribution well, a combined oil and sand separator and a sampling well. The difference is in the occupied area of \u200b\u200bequipment, in the number of containers and, accordingly, in the price. Free-standing modules look bulky and are more expensive than single-body modules.

The principle of operation is as follows:

After precipitation or snow melting, water containing suspended matter, oil products and other contaminants from industrial sites or residential (residential) territory enters the grates of rain wells and then collects through the collectors in an averaging tank, if VOCs are of storage type, or immediately in turn of a distribution well are supplied to the storm sewer treatment plant.

The distribution well serves to direct the very first dirty wastewater for cleaning, and after a while, when there will be no pollution on the surface, the conditionally clean wastewater through the bypass line will be discharged to the sewer or to a reservoir. Storm runoff goes through the first stage of cleaning in a sand catcher, in which gravitational sedimentation of insoluble substances and partial floatation of free-floating oil products take place. Then, through the partition, they flow into an oil-oil separator, in which thin-layer modules are installed, due to which suspended solids settle to the bottom along an inclined surface, and most of oil particles rise to the top. The last stage of cleaning is an activated carbon sorption filter. Due to sorption absorption, the rest of the oil particles and small mechanical impurities are captured.

This chain allows you to provide a high degree of purification and discharge the treated water into the reservoir.

For example, for oil products up to 0.05 mg / l, and for suspended solids up to 3 mg / l. These indicators fully comply with the current regulations governing the discharge of treated water into fishery reservoirs.

VILLAGE CLEANING FACILITIES

Currently, a large number of autonomous settlements are being built near megalopolises, which make it possible to live in comfortable conditions "in nature" without interrupting the usual urban life. Such settlements, as a rule, have a separate water supply and sewerage system, since there is no way to connect to the central sewerage system. The compactness and mobility of such treatment plants allows avoiding huge installation and construction costs.

However, despite their small size, the modules contain all the necessary equipment for complete biological treatment and disinfection of wastewater with the achievement of quality indicators of treated wastewater that meet the requirements of SanPiN 2.1.5.980-00. The undoubted advantage is the complete factory readiness of block containers, ease of installation and further operation.

TREATMENT FACILITIES FOR THE CITY

Big City - large treatment facilities (OS). It is logical, because the consumption of wastewater entering for treatment directly depends on the number of inhabitants: the rate of water disposal is equal to the rate of water consumption. And for a large volume of liquid, appropriate containers and reservoirs are needed. This fact generates interest in the design and operation of such OS.

When designing the sewage networks of a settlement, the load on the pipelines is taken into account, which are selected based on the passage of the required amount of runoff. In order not to bury pipes of a very large diameter, through which the contaminated liquid would be transported to the vast areas of treatment facilities, several wastewater treatment plants are being built in large cities.

Thus, the metropolis is divided into several "cities" (districts), and for each of them a cleaning station is designed.

A good example are the treatment facilities in the capital of Russia, among which there are Lyuberetskie with a capacity of 3 million m 3 / day - the largest in Europe. The main unit - the old modernized OS, providing half of the plant's capacity, the other two units - 1 million m 3 / day and 500 thousand. m 3 / day.

The peculiarities of the device of such wastewater treatment plants are the increased size of the structures in comparison with the wastewater treatment plants of other cities: settling tanks with a diameter of 54 meters, and the canals are comparable to small rivers.

From the point of view of technology, everything is standard: mechanical cleaning, settling, biological treatment, secondary settling, and disinfection. You can read on our website.

The main feature is only in what kind of structures they have for these stages of processing. For example, Moscow, as you know, was not built immediately, but it has always been a great source for sewage treatment plants. Reinforced concrete structures were built, which today have undergone several reconstructions and modernizations. Due to a decrease in the amount of diluted pure water some of the previously built structures are mothballed or used for other purposes. This is also the feature of the OS device: the old channels of the sand traps become an intermediate reservoir, the aeration tank corridor is transformed and works a little differently.

The main thing that significantly distinguishes the OS of large cities from their smaller brothers is closed structures.

In other words, a roof is mounted on all structures built in the 60s and 70s. This is done in order to eliminate the odor that can spread to new buildings, which, in turn, have arisen due to the geographical expansion of the metropolis. And if earlier the wastewater treatment plant was significantly removed from the city, now it is located near new residential complexes.

For the same reason, sprayers are installed on such operating systems that release special substances that neutralize the odors of the effluent.

Any treatment plant is a complex interconnection of processes. Of course, they will cope with their task 100%, but there is no need to complicate their work. Waste - in the trash, plumbing - as intended.

The Village goes on to explain what the townspeople use every day. In this issue - the sewerage system. After we press the flush button on the toilet, close the faucet and go about our business, the tap water turns into waste water and begins its journey. To get back to the Moskva River, she needs to go through kilometers of sewer networks and several stages of cleaning. How this happens, The Village found out by visiting the city's sewage treatment plant.

Through the pipes

At the very beginning, water enters the inner pipes of the house with a diameter of only 50-100 millimeters. Then it goes along the network a little wider - courtyards, and from there - into the street. At the border of each courtyard network and at the place of its transition to the street, a viewing well is installed through which you can monitor the operation of the network and clean it if necessary.

The length of the city sewer pipes in Moscow is more than 8 thousand kilometers. The entire territory, through which the pipes pass, is divided into pool parts. The section of the network that collects waste water from the pool is called a collector. Its diameter reaches three meters, which is twice as large as a pipe in a water park.

Mainly due to the depth and natural topography of the territory, water flows through the pipes by itself, but in some places it is required pumping stations, there are 156 of them in Moscow.

Wastewater flows to one of four wastewater treatment plants. The cleaning process is continuous, with peaks of hydraulic load occurring at 12 noon and 12 noon. The Kuryanovsk wastewater treatment plant, which is located near Maryino and is considered one of the largest in Europe, receives water from the southern, south-eastern and south-western parts of the city. Wastewater from the northern and eastern parts of the city goes to treatment plants in Lyubertsy.

Treatment plants

The Kuryanovsk treatment facilities are designed for 3 million cubic meters of wastewater per day, but only one and a half are supplied here. 1.5 million cubic meters is 600 Olympic swimming pools.

Previously, this place was called aeration station, it was launched in December 1950. Now the sewage treatment plant is 66 years old, and 36 of them Vadim Gelievich Isakov worked here. He came here as a foreman of one of the workshops and became the head of the technological department. When asked whether he expected to spend his whole life in such a place, Vadim Gelievich replies that he no longer remembers, it was so long ago.

Isakov says that the station consists of three cleaning blocks. In addition, there is a whole complex of facilities for processing sediments that are formed in the process.

Mechanical cleaning

Turbid and fetid waste water comes to the treatment plant warm. Even in the coldest time of the year, its temperature does not drop below plus 18 degrees. Waste water is met by a receiving and distribution chamber. But what happens there, we will not see: the camera was completely closed so that the smell did not spread. By the way, the smell of the huge (almost 160 hectares) territory of the sewage treatment plants is quite tolerable.

After that, the stage of mechanical cleaning begins. Here, on special grates, debris is retained, which sailed along with the water. Most often these are rags, paper, personal hygiene products (napkins, diapers), as well as food waste - for example, potato peelings and chicken bones. “What you can not meet. It happened that bones and skins came from meat-processing factories, ”they say with a shudder at the treatment plant. From the pleasant - only gold jewelry, although we did not find eyewitnesses of such a catch. Seeing the trash grid is the worst part of the tour. In addition to all the nasty things, many, many slices of lemons were stuck in it: “You can guess the season by the contents,” the employees say.

A lot of sand comes with wastewater, and so that it does not settle on structures and does not clog pipelines, it is removed in sand traps. Sand in liquid form enters a special area, where it is washed with technical water and becomes common, that is, suitable for improvement. Sewage treatment plants use sand for their own needs.

The stage of mechanical cleaning in primary sedimentation tanks is coming to an end. These are large reservoirs in which fine suspended matter is removed from the water. Here water comes in muddy, and leaves clear.

Biological treatment

Biological cleaning begins. It takes place in structures called aerotanks. They artificially support the vital activity of a community of microorganisms, which is called activated sludge. Organic pollution in water is the most desirable food for microorganisms. Air is supplied to the aeration tanks, which prevents the sludge from settling, so that it comes into contact with waste water as much as possible. This continues for eight to ten hours. “In any natural body of water, similar processes take place. The concentration of microorganisms there is hundreds of times lower than we create. Under natural conditions it would have lasted weeks and months, ”says Isakov.

The aeration tank is a rectangular reservoir, divided into sections, in which the waste water snakes in. “If you look through a microscope, then everything is crawling, moving, moving, floating. We make them work for our benefit, ”says our guide.

At the outlet of the aeration tanks, a mixture of purified water and activated sludge is obtained, which now need to be separated from each other. This problem is solved in secondary sedimentation tanks. There the sludge settles at the bottom, is collected by sludge pumps, after which 90% is returned to the aeration tanks for a continuous cleaning process, and 10% is considered excessive and disposed of.

Return to the river

Biologically treated water undergoes tertiary treatment. To check it, it is filtered through a very fine sieve, and then it is discharged into the outlet channel of the station, on which there is an ultraviolet disinfection unit. UV disinfection is the fourth and final cleaning step. At the station, the water is divided into 17 channels, each of which is illuminated by a lamp: the water in this place takes on an acidic hue. This is the most modern and largest such block in the world. Although it did not exist according to the old project, earlier they wanted to disinfect water with liquid chlorine. “It's good that it didn't come to that. We would have destroyed all life in the Moscow River. The reservoir would be sterile, but dead, ”says Vadim Gelievich.

In parallel with water purification, the sludge is dealt with at the station. The sediment from the primary clarifiers and the surplus activated sludge are processed together. They enter the digesters, where at a temperature of plus 50–55 degrees, the fermentation process takes place for almost a week. As a result, the sediment loses its ability to rot and does not emit an unpleasant odor. Then this sludge is pumped to dewatering complexes outside the Moscow Ring Road. “30-40 years ago, the sediment was dried on sludge areas in natural conditions. This process lasted from three to five years, now instant dehydration. The sediment itself is a valuable mineral fertilizer, in soviet times he was popular, the state farms took him with pleasure. But now nobody needs it, and the station pays for disposal up to 30% of the total costs of cleaning, ”says Vadim Gelievich.

One third of the sludge breaks down, turning into water and biogas, which saves on disposal costs. Part of the biogas is burned in the boiler house, and part is sent to the combined heat and power plant. A thermal power plant is not an ordinary element of wastewater treatment plants, but rather a useful addition that gives treatment facilities a relative energy independence.

Fish in the sewer

Previously, an engineering center with its own production base was located on the territory of the Kuryanovskie treatment plant. Employees conducted unusual experiments, for example, they bred sterlet and carp. Some of the fish lived in tap water, and some in the sewer, which was purified. Now fish is found only in the discharge channel, there are even signs "Fishing is prohibited."

After all the purification processes, the water flows through the discharge canal - a small river 650 meters long - to the Moscow River. Here and wherever the process takes place in the open air, there are many seagulls floating on the water. “They do not interfere with the processes, but they spoil the aesthetic appearance", Isakov is sure.

The quality of the treated wastewater discharged into the river is much better than the water in the river for all sanitary indicators. But it is not recommended to drink such water without boiling.

The volume of treated wastewater is equal to about a third of all water in the Moscow River above the discharge. If the sewage treatment plants were out of order, the settlements downstream would be on the brink of environmental disaster. But this is almost impossible.

Sewage treatment facilities OS, KOS, BOS.

One of the main ways to protect the natural environment from pollution is to prevent the ingress of untreated water and other harmful components into water bodies. Modern treatment facilities are a complex of engineering and technical solutions for the consistent filtration and disinfection of contaminated effluents in order to reuse them in production or for descent into natural reservoirs. For this, a number of techniques and technologies have been developed, which will be discussed below.

More about wastewater treatment technology

Since centralized sewage systems are not laid in all places, and some industrial enterprises require preliminary preparation of effluents, today local sewage facilities are very often equipped. They are also in demand in private houses, country cottage townships and detached housing estates, industrial enterprises, workshops.

Wastewaters differ in the source of pollution: domestic, industrial and surface (derived from atmospheric precipitation). Domestic wastewater is called household waste. They consist of contaminated water removed from showers, toilets, kitchens, canteens and hospitals. The main pollutants are physiological and household waste.

Industrial effluents include water masses that were formed when:

- performing various production and technological operations;

- washing raw materials and finished products;

- cooling equipment.

Also this type includes water pumped out from the bowels during the extraction of minerals. Industrial waste is the main source of pollution here. They may contain toxic, potentially hazardous substances, as well as waste that can be recovered and used as secondary raw materials.

Surface (atmospheric) drains most often contain only mineral contaminants; minimum requirements are imposed on their treatment. In addition, wastewater is classified according to the concentration of various pollutants. These characteristics influence the choice of the method and the number of cleaning steps. To determine the composition of the equipment, the need for construction, as well as the capacity of various types of structures, a calculation is made for the production of wastewater treatment.

The main stages of cleaning

At the first stage, mechanical wastewater treatment is carried out, the purpose of which is filtration from various insoluble impurities. For this, special self-cleaning grates and sieves are used. Detained waste, together with other sludge, is sent for further processing or taken to landfills along with solid domestic waste.

In the sand trap, fine particles of sand, slag and other similar mineral elements are deposited under the influence of gravity. In this case, the filtered composition is suitable for further use after processing. The rest of the undissolved substances are reliably retained in special sedimentation tanks and septic tanks, and fats and oil products are extracted using grease traps, oil traps and flotation devices. At the stage of mechanical treatment, up to three quarters of mineral contaminants are removed from waste streams. This ensures the uniformity of the liquid supply to the next processing stages.

After that, biological methods of purification are used, performed with the help of microorganisms and protozoa. The first structure where water enters at the biological stage is special primary sedimentation tanks, in which suspended organic matter settles. At the same time, another type of settling tank is used, in which activated sludge is removed from the bottom. Biological treatment removes more than 90% of organic contaminants.

At the physicochemical stage, there is a purification from dissolved impurities. This is done using special techniques and reagents. Coagulation, filtration and settling are used here. Along with them, various additional processing technologies are used, including: hyperfiltration, sorption, ion exchange, removal of nitrogen-containing substances and phosphates.

The last stage of treatment is the chlorine disinfection of the liquid from the remaining bacterial contamination. The diagram below shows in detail all the steps described, indicating the equipment that is used in each step. It is important to note that treatment methods for different manufacturing plants differ depending on the presence of certain pollutants in the wastewater.

Features and requirements for the arrangement of treatment facilities

Domestic wastewater is classified as uniform in composition, since the concentration of pollutants depends only on the volume of water consumed by residents. They contain insoluble impurities, emulsions, foams and suspensions, various colloidal particles, and other elements. Most of them are mineral and soluble substances. For the treatment of domestic wastewater, a basic set of treatment facilities is used, the principle of which is described above.

In general, domestic sewerage systems are considered simpler, since they are constructed to treat wastewater from one or more private houses and outbuildings. They do not have requirements for relatively high performance. For this purpose, specially designed installations are used that provide biological wastewater treatment.

Thanks to them, in suburban housing, it became possible not only to equip a shower, bathroom or toilet, but also to connect various household appliances. Usually, such installations are easy to install and operate, and do not require additional components.

For industrial effluents, the composition and the degree of pollution vary depending on the nature of the production, as well as the options for using water to support the technological process. In production food products wastewater is characterized by high pollution with organic substances, therefore, biological is considered the main method of treating such water. The best option is to use the aerobic and anaerobic methods or a combination of both.

In other industries, the main problem is the treatment of oily and greasy effluents. For such enterprises, special oil separators or grease traps are used. But the safest for environment are considered water circulation systems for purification of polluted water. Such local cleaning complexes are installed at car washes, as well as at manufacturing plants. They allow organizing a closed cycle of water use without discharging it into external water bodies.

To determine the method of organizing treatment and the choice of a specific structure, special systems and methods are used (there are many enterprises, therefore the process must be individualized). Of no small importance is the price of equipment and work on its installation. Only specialists will help you choose the best option for each case.

Send a request * Get advice

Urban Wastewater Treatment Plant

1. Appointment.

Water purification equipment is designed to purify urban wastewater (a mixture of domestic and industrial wastewater from municipal facilities) up to the standards for discharge into a reservoir of fish-economic purposes.

2. Scope of application.

The capacity of the treatment plant is from 2500 to 10000 cubic meters / day, which is equivalent to the consumption of wastewater from a city (village) with a population of 12 to 45 thousand people.

Estimated composition and concentration of pollutants in the source water:

- COD - up to 300 - 350 mg / l

- BODpoln - up to 250 -300 mg / l

- Suspended substances - 200-250 mg / l

- Total nitrogen - up to 25 mg / l

- Ammonium nitrogen - up to 15 mg / l

- Phosphates - up to 6 mg / l

- Petroleum products - up to 5mg / l

- Surfactant - up to 10mg / l

Standard cleaning quality:

- BODfull - up to 3.0 mg / l

- Suspended substances - up to 3.0 mg / l

- Ammonium nitrogen - up to 0.39 mg / l

- Nitrite nitrogen - up to 0.02 mg / l

- Nitrate nitrogen - up to 9.1 mg / l

- Phosphates - up to 0.2 mg / l

- Petroleum products - up to 0.05 mg / l

- Surfactant - up to 0.1mg / l

3. Composition of treatment facilities.

The technological scheme of wastewater treatment includes four main blocks:

- mechanical cleaning unit - for removing large waste and sand;

- complete biological treatment unit - to remove the bulk of organic contaminants and nitrogen compounds;

- block for deep post-treatment and disinfection;

- sludge processing unit.

Mechanical wastewater treatment.

To remove coarse impurities, mechanical strainers are used, which provide effective removal of dirt larger than 2 mm. Sand removal is carried out on grit traps.

Waste and sand removal is fully mechanized.

Biological treatment.

At the stage of biological treatment, nitri-denitrifying aeration tanks are used, which ensures the parallel removal of organic matter and nitrogen compounds.

Nitri-denitrification is necessary to ensure the discharge standards for nitrogen compounds, in particular, its oxidized forms (nitrites and nitrates).

The principle of operation of such a scheme is based on the recirculation of a part of the sludge mixture between the aerobic and anoxic zones. In this case, the oxidation of the organic substrate, the oxidation and reduction of nitrogen compounds does not occur sequentially (as in traditional schemes), but cyclically, in small portions. As a result, the nitri-denitrification processes proceed almost simultaneously, which makes it possible to remove nitrogen compounds without using an additional source of organic substrate.

This scheme is implemented in aeration tanks with the organization of anoxic and aerobic zones and with recirculation of the sludge mixture between them. The sludge mixture is recirculated from the aerobic zone to the denitrification zone by airlifts.

In the anoxic zone of the nitri-denitrifier aeration tank, mechanical (submersible mixers) stirring of the sludge mixture is provided.

Figure 1 shows a schematic diagram of the nitri-denitrifier aeration tank, when the return of the sludge mixture from the aerobic zone to the anoxic one is carried out under hydrostatic pressure through a gravity channel, the sludge mixture is fed from the end of the anoxic zone to the beginning of the aerobic one by airlifts or submersible pumps.

The initial wastewater and return sludge from the secondary sedimentation tanks are fed to the dephosphatation zone (anoxic), where the hydrolysis of high-molecular organic contaminants and the ammonification of nitrogen-containing organic compounds in the absence of any oxygen take place.

Schematic diagram of a nitri-denitrifier aeration tank with a dephosphatation zone

I - dephosphatation zone; II - denitrification zone; III - nitrification zone, IV - sedimentation zone

1- waste water;

2- return sludge;

4- airlift;

6- sludge mixture;

7- channel for circulating sludge mixture,

8- purified water.

Further, the sludge mixture enters the anoxic zone of the aeration tank, where the removal and destruction of organic pollutants, ammonification of nitrogen-containing organic pollutants by facultative microorganisms of activated sludge in the presence of bound oxygen (oxygen of nitrites and nitrates formed at the subsequent stage of purification) with simultaneous denitrification take place. Then the sludge mixture is directed to the aerobic zone of the aeration tank, where the final oxidation of organic substances and nitrification of ammonium nitrogen with the formation of nitrites and nitrates take place.

The processes taking place in this zone necessitate intensive aeration of the treated wastewater.

Part of the sludge mixture from the aerobic zone enters the secondary settling tanks, and the other part returns to the anoxic zone of the aerobic tank for denitrification of oxidized forms of nitrogen.

This scheme, in contrast to traditional ones, allows, along with effective removal of nitrogen compounds, to increase the efficiency of removal of phosphorus compounds. Due to the optimal alternation of aerobic and anaerobic conditions during recirculation, the ability of activated sludge to accumulate phosphorus compounds increases 5-6 times. Accordingly, the efficiency of its removal with excess sludge also increases.

However, in the case of an increased content of phosphates in the source water, in order to remove phosphates to a value below 0.5-1.0 mg / l, it will be necessary to treat the purified water with iron or aluminum containing (for example, aluminum oxychloride) reagent. It is most advisable to introduce the reagent before the post-treatment facilities.

Waste water clarified in secondary sedimentation tanks is sent for additional treatment, then for disinfection and further into the reservoir.

The principal view of the combined structure - nitri-denitrifier aeration tank is shown in Fig. 2.

Post-treatment facilities.

BIOSORBER - installation for deep post-treatment of waste water. More detailed description and general views installations.

BIOSORBER - see the previous section.

The use of a biosorber makes it possible to obtain water purified to the MPC standards of a fishery reservoir.

The high quality of water purification on biosorbers allows using UV installations for the disinfection of effluents

Sludge treatment facilities.

Taking into account the significant volume of precipitation formed during the wastewater treatment process (up to 1200 cubic meters / day), to reduce their volume, it is necessary to use structures that ensure their stabilization, compaction and mechanical dehydration.

For aerobic stabilization of precipitation, structures similar to aeration tanks with a built-in sludge compactor are used. Such a technological solution makes it possible to exclude the subsequent decay of the resulting sediments, as well as to approximately halve their volume.

A further decrease in volume occurs at the stage of mechanical dewatering, which provides for preliminary thickening of the sediments, their reagent treatment, and then dehydration in filter presses. The volume of dewatered sludge for a plant with a capacity of 7000 m3 / day will be approximately 5-10 m3 / day.

The stabilized and dewatered sludge is sent to storage at sludge pads. The area of \u200b\u200bthe sludge pads in this case will be approximately 2000 sq. M (the capacity of the treatment plant is 7000 m3 / day).

4. Constructive design of treatment facilities.

Structurally, the treatment facilities for mechanical and complete biological treatment are made in the form of combined facilities based on oil reservoirs with a diameter of 22 and a height of 11 m, closed from above with a roof and equipped with ventilation, internal lighting and heating systems (the coolant consumption is minimal, since the main volume of the structure is occupied by source water, which has temperature in the range of at least 12-16 degrees).

The productivity of one such facility is 2500 cubic meters / day.

The aerobic stabilizer with a built-in sludge compactor is made similarly. The diameter of the aerobic stabilizer is 16 m for stations with a capacity of up to 7.5 thousand cubic meters / day and 22 m - for a station with a capacity of 10 thousand cubic meters / day.

For post-treatment stage placement - based on installations BIOSORBER BSD 0,6, installations for the disinfection of treated effluents, a blower station, a laboratory, utility and utility rooms, a building 18 m wide, 12 m high and long for a station with a capacity of 2500 cubic meters / day - 12 m, 5000 cubic meters / day - 18, 7500 - 24 and 10000 cubic meters, m / day - 30 m.

Specification of buildings and structures:

- combined facilities - nitri-denitrifiers aerotanks with a diameter of 22 m - 4 pcs;

- industrial and service building 18x30 m with a post-treatment unit, a blower station, a laboratory and amenity premises;

- combined structure aerobic stabilizer with built-in sludge compactor, diameter 22m - 1 pc .;

- gallery 12 m wide;

- sludge platforms 5 thousand sq. m.